Phone:

(701)814-6992

Physical address:

6296 Donnelly Plaza

Ratkeville, Bahamas.

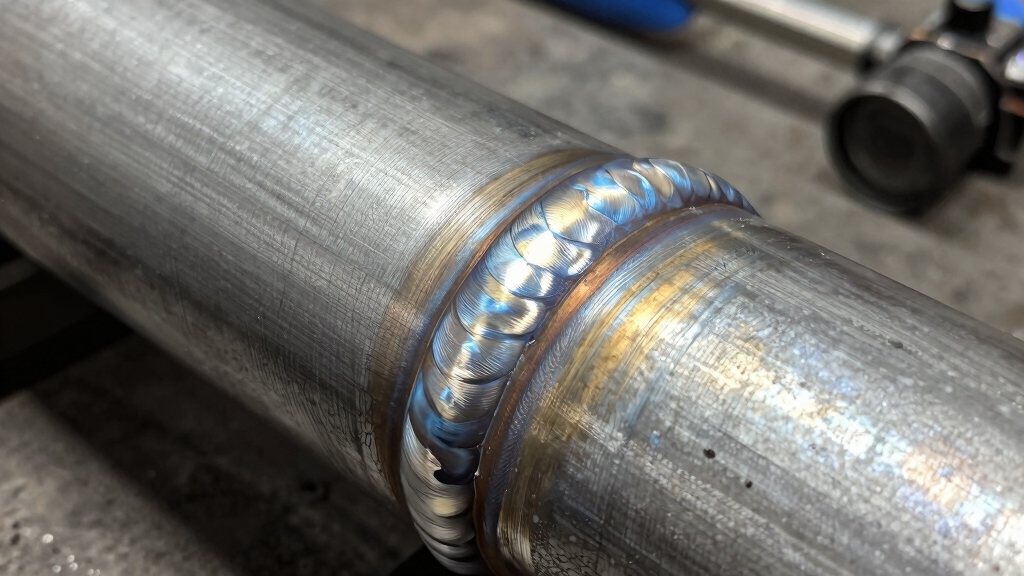

A CJP weld (Complete Joint Penetration) guarantees full-thickness fusion through the entire joint, giving you base-metal strength and optimal load transfer. You’ll achieve maximum fatigue resistance and structural integrity by fully fusing weld and base metal.

CJP welds require precise groove prep, skilled welders, and often backing or back gouging to confirm fusion. They’re critical in high-stress connections but come with higher costs and inspection demands. Understanding their types, standards, and alternatives helps you select the right weld for your project.

A Complete Joint Penetration (CJP) weld is a groove weld where the weld metal fully extends through the entire thickness of the joint, ensuring fusion between the weld and base metal across the full joint depth.

A CJP weld fully penetrates the joint thickness, ensuring complete fusion with the base metal throughout.

When you implement a CJP weld, you guarantee that the weld metal bridges the entire cross-section, providing a strength equal to the base metal when using matching filler per AISC 360-16 Table J2.5.

This approach applies primarily to groove welds in statically or cyclically loaded structures, where full penetration is vital.

You’ll find the term “complete penetration” occasionally used, but it aligns with CJP’s definition.

Understanding this weld type requires recognizing its role in ensuring structural integrity by eliminating unbonded regions within the joint thickness.

This is essential for reliable load transfer.

Achieving a CJP weld typically requires precise control of heat input and sequential welding passes to maintain joint integrity and minimize distortion.

Hey there! So, let’s talk about why full fusion is super important when it comes to CJP weld strength.

You really need full fusion to make sure there’s a complete metallurgical bond throughout the entire thickness of the joint. This not only guarantees the integrity of the joint but also ensures optimal load transfer.

If you don’t achieve full fusion, you might end up with stress concentrations and continuity issues that can lead to premature weld failure. That’s definitely something you want to avoid if you care about structural performance.

Plus, when you aim for full fusion, you’re also reducing the chances of common weld defects. Things like lack of penetration or inclusions can really weaken the connection.

Radiographic and penetrant testing are commonly used to detect these fusion and penetration flaws to ensure weld quality.

Because full fusion guarantees the weld metal completely bonds with the base material throughout the joint thickness, it directly determines the structural integrity and strength of a Complete Joint Penetration (CJP) weld.

Without continuous fusion, stress concentrations and defects like lack of fusion or voids can form, critically weakening the joint. You must make certain:

This fusion integrity assures load transfer matches the base metal’s capacity, preventing premature failure.

It’s the fundamental criterion distinguishing CJP welds from partial penetration or fillet welds, directly affecting safety and performance in structural applications.

Achieving full fusion also requires careful control of welding parameters to minimize heat input and avoid defects that compromise joint quality.

When you rely on a CJP weld, the load transfer efficiency hinges on achieving full fusion throughout the joint thickness. Full fusion guarantees the weld metal and base metal form a continuous, defect-free bond, enabling the weld to carry loads as effectively as the base metal itself.

Without complete joint penetration, stress concentrations arise at partially fused zones, reducing strength and potentially initiating cracks under static or cyclic loading. The weld’s capacity matches the base metal per AISC 360-16 Table J2.5 only when full fusion is verified, eliminating weak interfaces.

Hence, meticulous groove preparation, precise weld parameters, and skilled execution are crucial to maintain uniform metallurgical continuity. This ensures the CJP weld transfers loads efficiently and performs reliably under demanding structural conditions.

Welding is a critical step within fabrication that provides permanent metal bonds and structural integrity to assembled components, emphasizing the importance of welding quality control in producing strong CJP welds.

Achieving full fusion throughout the joint thickness not only guarantees effective load transfer but also prevents common weld defects that compromise CJP weld strength.

You must make certain complete fusion to avoid defects like lack of penetration, slag inclusions, porosity, and cracks, which critically reduce structural integrity.

To prevent these issues, focus on:

Additionally, selecting welding rods with deep penetration capability helps ensure complete root fusion and structural soundness.

Though guaranteeing full joint penetration demands meticulous preparation and execution, CJP welds rely on precise groove design and controlled welding techniques to fuse the weld metal completely through the joint thickness.

You start by preparing a groove with a suitable bevel angle, often around 50 degrees, and precise root face and opening dimensions to facilitate complete fusion.

Backing methods, such as backing strips or back gouging, support weld metal flow and root fusion, especially in double-sided welds.

You control welding parameters, heat input, travel speed, and filler deposition to avoid defects and maintain full penetration.

For single-sided welds without backing, you need advanced root control and certified welders to achieve consistent fusion.

This controlled approach guarantees the weld metal penetrates the entire joint depth, matching base metal strength and meeting structural standards.

Achieving full joint penetration welds requires extensive training and practice to develop the precision and control necessary for defect-free results.

Because different joint configurations and access conditions demand tailored approaches, understanding the distinct types of Complete Joint Penetration (CJP) welds is essential for selecting the proper method.

You’ll encounter two primary CJP weld types, each suited for specific scenarios:

Use Type 1 when maximum strength and full joint fusion are critical in large structural members.

Choose Type 2 for smaller diameter tubes or restricted access, balancing quality with fabrication constraints.

Modern welding techniques such as those utilizing inverter welding machines enable precise control over current and heat input, which is crucial for achieving defect-free CJP welds.

When you compare CJP and PJP welds, one of the first things you’ll notice is that CJP welds provide full joint strength. That’s because they fill the entire joint thickness, which is quite different from PJP welds that only offer partial penetration.

This difference is pretty significant, especially when it comes to fatigue performance. CJP welds are known for their superior durability under cyclic loads, making them a strong choice for heavy-duty applications.

But, of course, there’s always a trade-off, right? While CJP welds have their advantages, you also need to consider the higher cost and complexity that come with producing them. It’s definitely something to weigh carefully when deciding which type of weld is best for your project.

Proper polarity selection, such as using DCEP polarity, can help optimize penetration and weld quality in applications requiring full joint penetration.

Understanding the strength differences between Complete Joint Penetration (CJP) and Partial Joint Penetration (PJP) welds is crucial for selecting the appropriate weld type in structural applications.

CJP welds provide superior strength due to full fusion through the joint thickness, eliminating stress concentration points common in PJP welds. Specifically:

Choosing CJP guarantees maximum load capacity, while PJP balances strength and economy. Maintaining certification continuity is essential for welders performing these critical weld types to ensure quality and compliance with industry standards.

Evaluating fatigue performance reveals that Complete Joint Penetration (CJP) welds consistently outperform Partial Joint Penetration (PJP) welds in resisting cyclic stresses.

Because CJP welds provide full-thickness fusion between base metals, they eliminate stress concentrations common in PJP welds where incomplete penetration creates inherent discontinuities.

This full fusion reduces crack initiation sites, enhancing fatigue life under fluctuating loads.

In contrast, PJP welds, with partial throat thickness, exhibit reduced load transfer efficiency and higher susceptibility to crack propagation.

When you select CJP welds for cyclically loaded structures, you ensure fatigue strength closely approaches that of the base metal.

This advantage is essential in high-cycle fatigue scenarios or critical connections where failure prevention is paramount.

Consequently, CJP welds deliver superior fatigue resistance, justifying their specification despite fabrication complexity.

Proper preheating and controlled cooling can further improve weld durability by minimizing residual stresses and cracking risks in critical joints. heat treatment

Although Complete Joint Penetration (CJP) welds offer superior strength and fatigue resistance compared to Partial Joint Penetration (PJP) welds, they demand considerably higher cost and complexity in fabrication.

When you choose CJP welds, expect increased resource requirements and technical challenges. Here’s how they compare:

You must weigh these factors carefully. CJP excels in load capacity but at a premium in cost and complexity.

Complete joint penetration (CJP) welds are commonly employed in applications where full structural strength and fatigue resistance are critical, such as groove welds in T-joints and butt joints subjected to static or cyclic loads.

CJP welds ensure full strength and fatigue resistance in critical T-joint and butt joint applications.

You’ll find CJP welds specified in heavy structural steel connections, especially where the weld must match or exceed the base metal’s tensile strength per AISC 360-16.

They’re essential in hollow structural section (HSS) connections under fatigue loading, ensuring reliable load transfer without strength reduction.

In pipeline and pressure vessel fabrication, CJP welds guarantee leak-tight joints under high pressure.

When you require full-capacity welds with certified quality, such as in AWS D1.1 prequalified joints with backing or back gouging, CJP welds become the preferred choice.

Their application is indispensable where failure isn’t an option.

To ensure proper fusion in CJP welds, especially when dealing with unbacked single-side procedures, you’ll definitely need highly skilled welders who hold a 6GR certification. It’s crucial!

Now, labor intensity can really ramp up here. You’ve got to account for precise groove preparation, multiple weld passes, and sometimes even back gouging. All these factors can really add to the complexity.

As a result, you’ll find that both labor and material costs rise significantly when you compare CJP welds to partial or fillet weld options. It’s something to keep in mind when planning your projects!

Mastering CJP welds demands advanced skills and stringent certification, especially for single-sided, unbacked welds requiring precise root control. You must achieve full joint fusion without backing, which challenges even experienced welders.

Certification standards like AWS D1.1 require you to hold a 6GR welder qualification to guarantee competence. Key aspects you need to focus on include:

Without these skills and certifications, your CJP welds risk failure under cyclic or static loads, undermining structural safety and code compliance.

Maneuvering the labor and material costs of CJP welds requires careful consideration of their inherent complexity and resource demands.

You’ll face higher labor expenses due to the need for skilled welders with 6GR certification, especially for unbacked single-side welds.

The fit-up precision and groove preparation increase time and effort, while multiple passes and back gouging drive up labor hours.

Material costs rise from the use of matching filler metals and potential backing materials or strips.

Additionally, the requirement for extensive inspection and testing adds indirect expenses.

While CJP welds deliver full joint strength, you must weigh these costs against alternative weld types like PJP or fillet welds.

These alternatives offer lower expenses but reduced fatigue performance and strength.

Your budgeting must reflect these trade-offs for efficient project execution.

When preparing grooves for CJP welds, you must guarantee precise bevel angles and root configurations to achieve full joint penetration and fusion throughout the thickness. Groove preparation appreciably impacts weld integrity and strength.

Precise bevel angles and root settings are crucial for full joint penetration and weld strength.

Typically, you should:

These steps reduce the risk of incomplete fusion and porosity, essential in static or cyclic loading scenarios. Following these groove preparation standards aligns with AWS D1.1 and CSA S59 requirements, assuring your CJP welds meet structural performance criteria.

Although achieving a proper CJP weld demands meticulous technique, you must also guarantee compliance with rigorous certification and testing standards to validate weld quality.

Standards like AWS D1.1, ASME IX, and EN ISO 15614 define welder qualifications and procedure qualification records (PQRs) specific to CJP welds.

Destructive and nondestructive tests, including radiographic and ultrasonic inspections, verify full joint penetration and fusion.

| Standard | Certification Scope | Testing Methods |

|---|---|---|

| AWS D1.1 | Welder & procedure qualification | Radiography, Ultrasonic Testing |

| ASME IX | PQR & WPS for pressure vessels | Bend Tests, Visual Inspection |

| EN ISO 15614 | Welding procedure qualification | Macro Etching, Hardness Testing |

| API 1104 | Pipeline welding standards | Radiography, Hydrostatic Testing |

Adhering to these standards guarantees structural integrity and compliance in CJP weld applications.

Since CJP welds demand high skill levels, precise preparation, and can incur significant costs, you should consider alternatives like partial joint penetration (PJP) welds or fillet welds where full strength isn’t critical.

These options offer cost-effectiveness and simpler fabrication without compromising safety when designed appropriately.

You should choose alternatives based on:

Evaluating these factors makes certain you apply the most efficient weld type without over-specifying CJP welds unnecessarily.

Welding position critically impacts CJP weld quality by influencing access, control, and fusion consistency.

When welding in challenging positions, like vertical or overhead, you’ll face gravity effects causing potential slag inclusion or incomplete fusion.

Maintaining precise root penetration and bead profile is harder, risking defects.

You must employ skilled techniques, proper electrode angles, and qualified certifications like 6GR to guarantee full joint penetration, especially in single-sided or tubular welds where position limits visibility and manipulation.

Picture a seam that must be flawless. Common defects in CJP welds include incomplete fusion, porosity, and root cracking, each threatening joint integrity.

You’ll face undercutting from improper groove angles and slag inclusions in multi-pass welds. Since CJP welds require full penetration, lack of fusion at the root or between passes can cause failures.

To avoid these, you must guarantee precise fit-up, correct technique, and thorough inspection throughout welding.

You inspect CJP welds for internal flaws primarily using non-destructive testing methods like ultrasonic testing (UT) and radiographic testing (RT).

UT helps detect subsurface cracks, lack of fusion, or porosity by sending sound waves through the weld. RT uses X-rays or gamma rays to reveal internal discontinuities on film or digital detectors.

You must follow relevant standards, AWS D1.1 or ASME IX, and ensure qualified inspectors perform these tests for reliable flaw detection.

You should select filler materials that match the base metal to guarantee strength equal to the parent metal, as specified in AISC 360-16 Table J2.5.

Using matching filler metals maintains full joint integrity in CJP welds, especially under cyclic or static loads.

For steel structures, low-hydrogen electrodes or solid wires compatible with the base steel grade provide ideal fusion and mechanical properties.

Avoid fillers that compromise toughness or cause excessive dilution.

Think of CJP welding as forging a steel fortress; it demands careful post-weld heat treatment (PWHT) to relieve stresses and refine microstructure.

You’ll need to apply PWHT thoughtfully, as CJP’s full penetration and thicker weld metal increase heat input, risking distortion or cracking.

Controlling temperature and cooling rates precisely guarantees uniform mechanical properties, maintains strength, and prevents residual stresses that could compromise fatigue life and structural integrity.

Think of a CJP weld as the backbone of a structure, where every fiber fuses completely, ensuring unyielding strength like a well-rooted tree standing firm against storms.

You rely on full joint penetration to distribute stresses evenly, preventing weak points that could fracture under pressure.

Though demanding in preparation and cost, CJP welds deliver unmatched integrity, making them indispensable when safety and durability can’t be compromised in your critical weld joints.