Phone:

(701)814-6992

Physical address:

6296 Donnelly Plaza

Ratkeville, Bahamas.

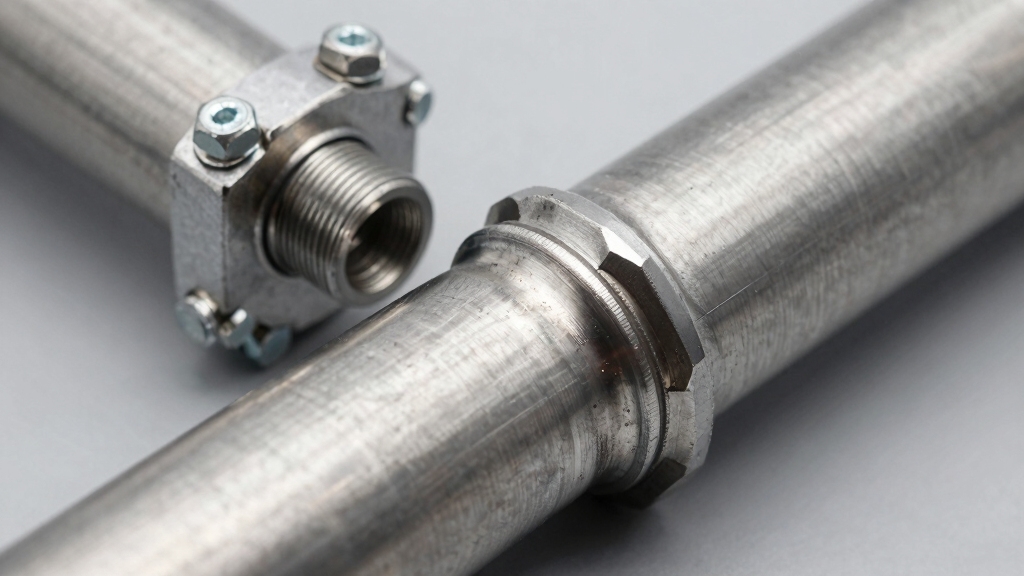

You can join two steel pipes without welding by using threaded joints, flanged connections, compression or push-fit fittings, mechanical couplings, or adhesives and press-fit systems.

Threaded joints suit low-pressure setups with pre-threaded pipes, while flanged joints provide high-pressure strength and easy disassembly.

Compression fittings offer mechanical seals, and push-fit fittings enable quick, tool-free assembly.

Mechanical couplings allow temporary repairs. Adhesive and press-fit methods create strong, non-invasive seals.

Understanding each method’s advantages helps you select the best option for your needs.

Although welding is a common method for joining steel pipes, you can achieve reliable connections without it by using several alternative joint types.

Threaded joints screw pre-threaded pipes together with couplings or elbows, ideal for low-pressure plumbing but unsuitable for high-stress applications.

Flanged joints use bolted flanges with gaskets to form leak-proof seals, offering mechanical strength and ease of disassembly. However, they’re limited to smaller pipe sizes and moderate pressures.

Compression fittings employ a nut and ferrule to create a mechanical seal, suitable for gas or hydraulic lines but vulnerable to vibration-induced loosening.

Push-fit fittings rely on internal O-rings for quick, tool-free connections in compatible pipe materials.

Mechanical couplings and clamps provide temporary repairs with minimal equipment.

Adhesives and press-fit systems offer strong, non-invasive seals, preserving pipe integrity and requiring surface preparation.

Choosing the appropriate joining method depends on factors such as structural demands, material types, and desired application conditions.

When selecting a non-welded joint for steel pipes, you must evaluate factors such as pressure requirements, pipe size, material compatibility, and ease of maintenance.

Choosing non-welded steel pipe joints requires assessing pressure, size, compatibility, and maintenance needs.

For high-pressure systems, flanged joints offer mechanical strength and reusability.

Compression fittings suit moderate pressures but risk loosening under vibration.

Threaded joints work well for smaller diameters in low-pressure setups, requiring pre-threaded pipes.

Mechanical couplings provide quick, temporary solutions but demand careful sealing to prevent leaks.

Adhesives and press-fit joints deliver strong bonds without altering pipe integrity but necessitate surface preparation and curing time.

You should also consider installation complexity and future disassembly needs to select a joint that balances performance and operational efficiency without welding.

Additionally, ensuring proper flange support can significantly enhance the joint’s strength and prevent premature failures in mechanical connections.

Threaded joints offer a reliable method to connect steel pipes without welding by utilizing pre-threaded pipe ends that screw into compatible fittings such as couplings, elbows, or unions.

This technique guarantees a secure mechanical connection ideal for plumbing and low-pressure systems.

When using threaded joints, keep these key points in mind:

Additionally, ensuring the pipes are made from galvanized steel can enhance corrosion resistance in outdoor or moist environments.

When it comes to flanged joints for steel pipes, you’ll find a variety of flange types out there. Each type is crafted for specific pressure ratings and connection requirements, which is pretty neat!

Now, when you’re installing these flanges, it’s super important to align them accurately. Trust me, getting that alignment right makes all the difference. And don’t forget to tighten those bolts to the specified torque values. This step is crucial for ensuring you have leak-proof seals.

But it doesn’t stop there! Regular maintenance is key to keeping everything running smoothly. Make it a habit to inspect the gaskets and retorque the bolts periodically. This little bit of effort goes a long way in making sure your joints remain reliable over time.

Additionally, using specialized primers or barrier coatings near the joint can help manage corrosion differences and extend joint longevity.

Although flanged joints provide a reliable and reusable connection for steel pipes without welding, selecting the appropriate flange type is critical to guarantee mechanical strength and leak-proof performance.

Each flange type suits different pressure ratings and installation conditions. You’ll primarily consider these types:

Choosing the correct flange involves analyzing pressure, temperature, and maintenance requirements to secure a secure, leak-free joint. When welding is necessary, applying weld-through primer can protect joints from corrosion while maintaining weld integrity.

When installing flanged joints for steel pipes, proper alignment and gasket placement are essential to guarantee a leak-proof seal and mechanical integrity.

You should evenly tighten bolts in a cross pattern to prevent flange distortion and ensure uniform pressure on the gasket.

Regular inspection and maintenance, checking bolt torque and gasket condition, are critical to avoid leaks and mechanical failure.

Replace gaskets showing wear or damage promptly.

Additionally, after assembly, it is important to ensure the flange surface is dry and clean to prevent corrosion and facilitate surface protection.

| Task | Frequency | Key Considerations |

|---|---|---|

| Bolt tightening | During installation | Use calibrated torque tools |

| Gasket inspection | Periodic (monthly) | Look for cracks or deformation |

| Flange alignment | During assembly | Align faces to prevent stress |

This disciplined approach maximizes flange joint reliability and service life.

When deciding between compression and push-fit fittings, it’s really important to think through your installation needs. For instance, compression fittings require a wrench for tightening, which can be a bit more labor-intensive.

On the other hand, push-fit options are super convenient because they allow for tool-free assembly—just push them together and you’re good to go!

Next, let’s talk about pressure ratings and seal integrity. Compression fittings can sometimes loosen if there’s a lot of vibration, which isn’t ideal. But push-fit seals are known for their reliability, especially in low to moderate pressure situations.

So, if you’re working in an environment where vibrations might be an issue, push-fit might be the better choice.

Oh, and don’t forget about material compatibility! Push-fit fittings are perfect for specific pipes like copper or PEX, but if you need to work with a wider range of steel pipe sizes, compression fittings might be your best bet. So, weigh your options carefully based on your project requirements.

Also, when working with metal pipes, it’s important to consider safety gear like gloves to protect your hands from cuts, burns, and other injuries during installation, ensuring a safer workflow and better hand safety.

Because compression and push-fit fittings serve similar functions but operate differently, selecting the right type depends on your installation environment and tool availability. You’ll want to evaluate these key installation requirements to make an informed choice:

Consider these factors carefully to optimize installation speed, reliability, and compatibility without welding. Additionally, understanding the material variations can help select the proper fitting type and installation method.

Evaluating pressure ratings and seal integrity plays a crucial role in choosing between compression and push-fit fittings.

Compression fittings rely on a ferrule compressed by a nut, creating a mechanical seal effective for low to moderate pressures. However, they’re vulnerable to loosening under vibration or elevated pressure spikes.

Push-fit fittings use internal O-rings to form a leak-proof seal, suitable for low to moderate pressures and quick installations. They’re limited to specific pipe materials.

When your system involves steady, moderate pressures and requires frequent disassembly, compression fittings offer adjustability with some risk of seal degradation.

Conversely, if you prioritize rapid installation and ease of maintenance in compatible materials, push-fit fittings provide reliable sealing without tools, albeit with stricter pressure limits. Assess system pressure profiles and seal longevity to select the best fitting type.

For applications involving steel pipes, it is important to consider welding methods and heat control to avoid damage when assembly requires joining beyond fittings.

Material compatibility plays a critical role when choosing between compression and push-fit fittings, as each system interacts differently with pipe materials.

Compression fittings rely on a ferrule that deforms around the pipe, making them ideal for rigid metals like copper or steel. Push-fit fittings use internal O-rings and are suited for flexible materials such as PEX or CPVC.

When deciding which to use, consider:

Additionally, selecting the correct fitting type and material is essential to prevent issues like corrosion resistance degradation that can occur with incompatible welding or joining methods.

Understanding these factors guarantees a secure, leak-proof joint without welding.

Mechanical couplings and clamps offer a practical solution when you need to join steel pipes quickly without welding.

You can install these devices with minimal tools, securing pipe ends tightly to restore flow or contain leaks temporarily.

Their design accommodates slight misalignments and varying pipe diameters, making them versatile across steel pipe sizes.

However, you must guarantee proper gasket placement and clamp torque to maintain an effective seal under pressure.

While cost-effective and reusable, these couplings are sensitive to pressure fluctuations and are best suited for emergency or short-term repairs rather than permanent joints.

Always assess system pressure and mechanical stresses before relying solely on mechanical couplings, as their sealing integrity depends on precise installation and ongoing monitoring.

When joining steel pipes without welding, adhesive and press-fit methods provide reliable alternatives that maintain pipe integrity.

These techniques eliminate the need for cutting, threading, or drilling, preserving the pipe’s structure and strength.

You’ll need to prepare surfaces meticulously for adhesive bonding to guarantee maximum strength and durability.

Press-fit systems rely on precise tooling to create uniform, high-pressure seals without compromising the pipe’s material.

Consider these key points:

Non-welded joints generally struggle with extreme temperature fluctuations because materials expand and contract differently, risking seal integrity.

You can use flanged joints with high-quality gaskets designed for thermal cycling, but most threaded, compression, or push-fit fittings may loosen or leak.

Adhesive or press-fit methods offer better thermal resilience but need precise surface prep and curing.

Non-welded joints can influence corrosion resistance depending on the method.

Threaded and flanged joints may trap moisture, accelerating corrosion if not properly sealed.

Compression and push-fit fittings rely on tight seals, but vibration can compromise them, inviting corrosion.

Mechanical clamps risk crevice corrosion due to uneven pressure.

Adhesives and press-fit systems, when correctly applied, maintain pipe integrity and reduce corrosion risk by avoiding heat-affected zones typical in welding.

You’ll want to give your non-welded steel pipe joints a bit of tender loving care.

Regularly inspect for signs of loosening or seal wear, especially at threaded or compression fittings. Maintain tightness without over-torquing bolts on flanged joints.

Keep joints clean and dry to prevent corrosion creep. Use appropriate lubricants or anti-seize compounds on threads, and promptly address vibrations or pressure fluctuations to preserve joint integrity and prolong service life.

You should always wear appropriate PPE, including gloves and safety glasses, to prevent injury from sharp edges or debris.

Make sure the work area is well-ventilated and free of flammable materials, especially when using adhesives or press-fit tools.

Verify pipe compatibility and inspect fittings for damage before assembly.

Use proper torque settings on threaded or bolted joints to avoid leaks or mechanical failure.

Finally, follow manufacturer guidelines precisely to make certain a secure, safe connection.

Non-welded joints can cause minor pressure drops due to internal fittings or seals slightly restricting flow.

Threaded or flanged joints introduce turbulence and small diameter changes, impacting flow rate marginally.

Compression and push-fit fittings also add minimal resistance but typically won’t materially affect system performance under normal conditions.

However, in high-pressure or critical flow scenarios, these effects might accumulate.

You should evaluate joint type carefully to maintain peak hydraulic efficiency.

Choosing the right non-welded method for joining steel pipes is like picking the perfect tool from a toolbox. Each fits a specific challenge. While welding offers permanence, threaded, flanged, or mechanical couplings provide flexibility and speed without the heat.

Compression fittings and adhesives might seem less robust but excel in quick fixes or sensitive environments. Balancing strength and convenience, these alternatives prove that joining steel pipes doesn’t always require a flame. Just the right approach is needed.