Phone:

(701)814-6992

Physical address:

6296 Donnelly Plaza

Ratkeville, Bahamas.

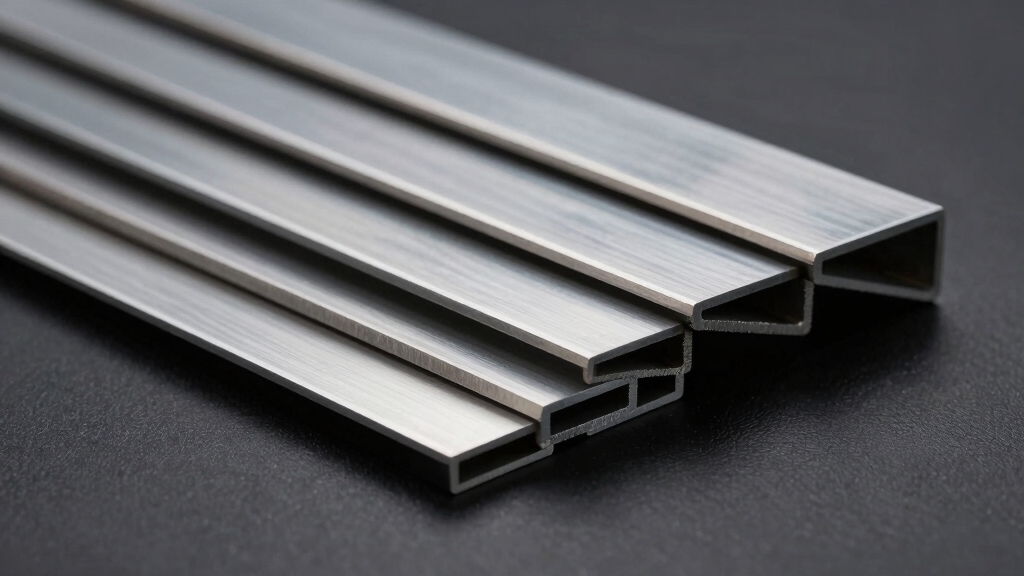

You’ll find automotive sheet metal thickness varies widely by panel and vehicle type.

Outer panels like door skins usually range from 0.7 to 1.2 mm (20 to 18 gauge), while structural reinforcements can exceed 2 mm (14 gauge or thicker).

Materials differ too; steel usually uses thinner gauges than aluminum, which requires thicker sheets for strength.

Replacement panels often run thinner than OEM originals, impacting fit and durability.

Understanding these variations is key to precise measurement and effective repair strategies.

Understanding standard gauge measurements is essential when working with automotive steel panels, as these gauges determine panel thickness and influence formability and strength. Proper selection of tools such as the correct drill bit size is crucial when modifying or repairing these panels.

Commonly, older passenger-car outer panels use 18 gauge, approximately 0.0478 inches (1.214 mm), while modern mass-production panels typically measure 20 gauge, about 0.0359 inches (0.911 mm).

Thinner 22 gauge panels, near 0.0299 inches (0.759 mm), appear frequently in recent repair literature. Remember, gauge numbers vary by material type; carbon steel, stainless steel, and aluminum each have different thickness equivalents for the same gauge.

Due to manufacturing tolerances and varied gauge systems, you should always verify thickness with material-specific charts. This precision guarantees proper panel matching, formability, and structural integrity during fabrication or repair work.

It’s important to note that gauge numbers are inversely related to thickness, meaning a higher gauge number indicates a thinner sheet metal.

When it comes to passenger cars, you’ll usually find that the panels are made from 16 to 20 gauge steel. It’s interesting to note that outer panels tend to be thinner than the structural ones. This design choice helps to balance weight with strength, which is super important for performance. Additionally, the thinner outer panels often require protective coatings like powder coating to prevent corrosion in harsh environments.

Now, the material you choose can also play a big role in thickness. For instance, stainless steel and aluminum require different gauges to achieve similar durability levels. So, knowing these variations is key! It ensures that everything fits properly and performs well across different areas of the vehicle.

Most reproduction sheet metal sold today ranges from 18 to 22 gauge, commonly 20 gauge, which is generally thinner than the original panels. This thinner gauge results in reduced vehicle weight compared to original examples.

Passenger car panels vary in sheet metal thickness depending on their function and location, reflecting a balance between weight, strength, and formability requirements.

Outer panels like hoods, fenders, and trunk lids typically range from 18 to 22 gauge steel (about 1.2 to 0.7 mm), with 20 gauge common for repairs.

Door skins usually fall between 20 and 22 gauge, balancing dent resistance and weight, while inner door reinforcements use thicker or higher-strength steels.

Roofs, pillars, and rocker panels employ gauges from 0.6 up to 1.0 mm, often incorporating advanced high-strength steels to reduce mass without compromising crash performance.

Galvanization for corrosion resistance frequently accompanies 0.6–0.8 mm body panels.

Aluminum panels follow distinct gauge-thickness mappings to meet stiffness requirements.

This strategic gauge variation optimizes structural integrity and manufacturability across passenger car body components.

Furthermore, the use of advanced high-strength steels allows for thinner gauges while maintaining safety and performance standards.

Although outer panels primarily focus on aesthetics and weight reduction, structural panels demand considerably greater thickness to guarantee strength and rigidity.

Structural components typically range from 14 to 10 gauge steel, spanning 0.0747 to 0.1345 inches. This ensures frame integrity and load-bearing capacity. Because thickness determines fabrication, these thicker panels allow for more robust bending and welding processes. Proper welding of these thicker structural steels often requires controlled heat input to maintain joint integrity and avoid distortion.

Outer panels, conversely, use thinner gauges—usually 20 to 16 gauge—balancing formability and surface durability with thicknesses from 0.0359 to 0.0598 inches.

Thickness varies by panel location: doors and fenders require thicker outer sheets for dent resistance, whereas roofs and hoods use lighter gauges to reduce weight.

Vehicle type also influences thickness. Trucks and commercial vehicles rely on heavier 10-14 gauge structural panels, while muscle cars utilize 16 gauge.

Understanding these variations helps you assess durability and performance across different automotive designs.

When comparing vehicle types, you’ll notice significant differences in sheet metal thickness driven by functional demands and panel location.

Passenger cars typically use 18–22 gauge (≈0.8–1.4 mm) for outer panels, with thicker 16–18 gauge (≈1.0–1.5 mm) on roofs and hoods to resist denting. Proper handling and cutting of these panels often require correct blades to avoid damage during fabrication.

Inner reinforcements reach 14–16 gauge (≈1.6–2.5 mm) for mounting strength.

Light trucks and SUVs employ 16–20 gauge (≈1.0–1.8 mm) exteriors, with heavier 14–16 gauge on load-bearing parts. Supporting and clamping the workpiece securely is essential when shaping these thicker sections to prevent vibration and ensure precision.

Structural zones integrate even thicker 14–12 gauge equivalents.

Luxury and performance vehicles vary thickness via tailored blanks, using 16–20 gauge outer skins plus ultra-high-strength steels or aluminum alloys (~1.2–2.0 mm aluminum). Specialized deburring and finishing techniques help maintain edge integrity in these complex materials.

Commercial vehicles demand thicker 14–10 gauge (≈1.9–3.4+ mm) panels in cargo and cab areas.

These variations reflect optimized balance between weight, strength, and durability for each application. Additionally, sheet metal is typically processed from rolled coils in standardized widths and lengths to facilitate manufacturing and handling sheet metal sizes.

Because reproduction panels often use thinner gauges and different steel grades than originals, you’ll notice significant variations in material properties and fitment.

Replacement panels typically come in 20–22 gauge, thinner than original 16–18 gauge steel. This reduces stiffness and dent resistance.

Replacement panels are thinner, typically 20–22 gauge versus original 16–18 gauge, reducing stiffness and dent resistance.

Different steel grades and coatings affect corrosion resistance and effective thickness. Moreover, understanding the thermal expansion differences between metals is important to anticipate distortion during welding.

Dimensional tolerances and tooling differences cause fitment challenges; you’ll often need trial-fitting, trimming, and adjusting hole patterns or flanges to match original attachment points.

Thinner panels alter structural performance during repairs, requiring adjusted welding techniques to avoid burn-through and reinforcement strategies to maintain rigidity. Using an Eastwood Sheet Metal Gauge can help accurately measure the thickness of both original and replacement panels to ensure proper welding settings.

You must account for tolerance stacking causing misalignments.

Understanding these differences is essential for accurate restoration, ensuring you balance originality, durability, and safety when selecting and installing replacement sheet metal panels.

Understanding gauge-to-millimeter conversions is essential for accurately selecting and measuring automotive sheet metal thickness. Since gauge numbers inversely relate to thickness, you must convert these values to millimeters for precision in fabrication. Here’s what you need to know:

Mastering these conversions guarantees you meet exacting automotive standards and maintain part integrity during manufacturing.

When it comes to auto body panels, steel and aluminum really take center stage. Each material has its own unique thickness and gauge standards, which are influenced by their specific properties.

For instance, steel panels usually fall within the range of 0.6 to 1.5 mm. This variation often depends on the grade of steel being used and its intended application. The choice of thickness also reflects the need to balance formability and weldability with structural strength.

On the other hand, aluminum alloys tend to require thicker gauges—typically around 0.8 to 2.0 mm. This added thickness helps them achieve the necessary stiffness and dent resistance that’s crucial in automotive design. However, maintaining the protective oxide film on aluminum surfaces is important to prevent corrosion and preserve material integrity. So, understanding these differences is key! It ensures you make the right material choices and maintain precision during the manufacturing process.

When comparing steel and aluminum for automotive body panels, you’ll notice aluminum generally requires greater thickness to match the stiffness and strength of steel due to its lower modulus of elasticity and differing yield strengths.

For example:

Additionally, selecting the correct welding filler wire and managing heat input are critical when fabricating or repairing these panels to maintain material integrity and performance.

You’ll find aluminum panels thicker but lighter, optimizing strength-to-weight ratios essential for modern vehicle efficiency and safety.

Matching the material to its appropriate thickness requires familiarity with gauge standards, which vary notably between steel types used in automotive body panels.

You’ll find carbon steel, stainless steel, and galvanized steel gauges differ slightly in thickness despite similar gauge numbers. Automotive body panels commonly range from 20 to 16 gauge, balancing strength and formability. It is important to remember that gauges are non-linear, and the same gauge number does not correspond to identical thicknesses across different materials. When working with galvanized steel, special care in welding is often necessary due to the presence of zinc coating hazards.

For corrosion resistance, galvanized steel uses thicker gauges aligned with carbon steel but adjusted for coating.

| Material | 18 Gauge Thickness (in/mm) |

|---|---|

| Carbon Steel | 0.0478 in / 1.214 mm |

| Stainless Steel | 0.0500 in / 1.270 mm |

| Galvanized Steel | Approx. 0.051 in / 1.294 mm |

This table highlights slight yet critical differences you’ll need to take into account in repairs or fabrication.

Although outer skin panels and structural components both contribute to a vehicle’s integrity, their thickness requirements differ markedly due to their distinct roles.

Outer skin panels typically range from 20 to 16 gauge (0.0359 to 0.0598 inches), balancing formability, weight, and dent resistance. Structural panels require thicker gauges, usually 14 to 10 (0.0747 to 0.1345 inches), to withstand impact and load. It is important to note that gauge numbers indicate thickness; lower gauge numbers correspond to thicker metal, which is crucial for matching material strength to vehicle safety needs. Proper heat input management during fabrication helps maintain panel strength and prevents distortion.

Consider these key points:

You must evaluate these factors precisely when selecting panel thickness.

Measuring sheet metal thickness accurately demands selecting the right tools and techniques tailored to the material and application.

Accurate sheet metal thickness measurement hinges on choosing appropriate tools and methods for each material and use case.

You’ll find mechanical micrometers offer high precision (1–10 µm) when calibrated and used with consistent force, ideal for spot checks.

Digital calipers provide quicker, less precise readings, so averaging multiple measurements is critical.

Non-contact methods like eddy-current or Hall-effect gauges suit conductive substrates, with your choice depending on magnetic properties.

Optical and laser gauges excel in high-speed, non-contact measurements on moving sheets.

Calibration is essential: always verify tools against certified standards and reference samples, especially for magnetic or conductive instruments.

For thin coated metals, capacitance-based sensing with specialized probes can achieve nanometer to micrometer accuracy, providing a highly stable measurement method for ungrounded or grounded samples. capacitance-based sensing

Employ multiple-point sampling across panels to account for thickness variability.

Zeroing instruments before use and following periodic re-calibration guarantees measurement reliability and traceability in your thickness assessments.

When working with varying sheet metal thicknesses, you must adjust repair and replacement techniques to prevent damage and guarantee structural integrity. Aluminum, for example, is preferred for dashboards and light, easy-to-work parts due to its light, soft properties. Thin metals demand stitch welding with .023 MIG wire to avoid burn-through. Thicker sections require arc initiation to control heat flow. Proper heat management, including annealing at 1,600°F and controlled cooling, prevents work hardening fractures.

Patch repairs focus on cutting only rusted weak spots and using corrugated .095-inch steel patches, seam-welded continuously per MOT standards. Mild steel is more forgiving in repairs and resists work-hardening and tearing, making it easier to weld in heavier sections.

Key considerations include:

Adapting techniques to thickness guarantees durable, precise restoration outcomes.

Temperature affects your auto sheet metal thickness measurements by causing thermal expansion or contraction, altering the metal’s dimensions slightly.

Steel and aluminum panels expand differently, with aluminum showing roughly twice the thickness change per degree Celsius.

If you don’t stabilize both your part and instrument temperature, you’ll get measurement errors.

Using temperature-compensated tools, equilibrating materials, and controlling the environment are essential to guarantee accurate, repeatable thickness readings.

Yes, paint and coatings definitely change the perceived thickness of sheet metal.

When you measure, the coating adds to the total thickness, often by 0.08 to 0.18 mm for OEM paint and even more with heavy aftermarket coatings, up to 2 mm.

This extra layer affects your readings and visual inspection, so you must compensate for coatings by subtracting their thickness or using calibrated instruments to get accurate bare-metal values.

You’ll want to use mechanical gauges, ultrasonic thickness gauges, laser measurement sensors, or advanced digital gauges for non-destructive thickness measurement.

Mechanical gauges provide quick, contact-based readings.

Ultrasonic gauges penetrate coatings for precise measurements.

Laser sensors deliver micron-level accuracy on moving sheets.

Advanced digital gauges handle ultra-thin layers and complex materials.

Each tool offers unique benefits, so you should select based on material type, coating presence, and measurement precision required.

Metal thickness directly influences your vehicle’s weight distribution by shifting mass toward the sections with thicker panels.

When you use thicker metal, especially in the body structure, you add weight higher up, slightly raising the center of gravity.

Conversely, thinner panels reduce overall mass and lower the center of gravity, often shifting weight toward the powertrain and suspension.

Balancing thickness optimizes load-bearing capacity while maintaining desired handling dynamics.

Yes, electric vehicles use different sheet metal thicknesses tailored to their unique design demands.

You’ll find thinner panels in non-structural areas due to lightweight aluminum alloys and high-strength steels, reducing overall mass.

However, critical zones like battery enclosures require thicker steel or reinforcements for crash protection.

You’ll also notice multi-material joints and variable thickness panels to optimize structural integrity, NVH control, and manufacturability in EVs’ specialized architectures.

Understanding auto sheet metal thickness is vital, as it varies like the layers of an onion, each serving a specific purpose.

You’ll find differences depending on the vehicle type, panel location, and whether the panel is original or replacement.

Accurately measuring thickness helps you choose the right repair techniques and materials.

Keeping these standards in mind guarantees structural integrity and peak performance, making your work precise and reliable every time.