Phone:

(701)814-6992

Physical address:

6296 Donnelly Plaza

Ratkeville, Bahamas.

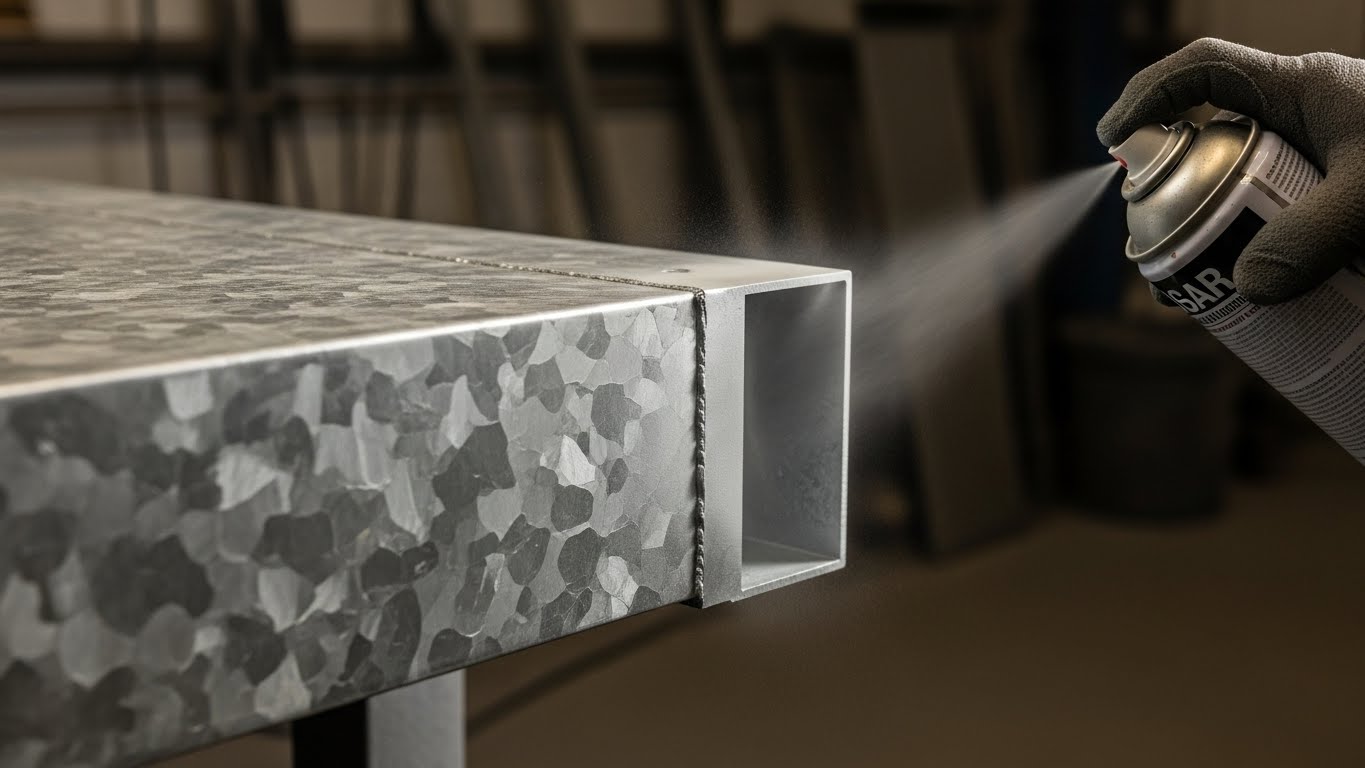

You can spray paint galvanized steel successfully, but only if you properly prepare the surface first. Clean off dirt, oils, and oxidation using degreasers, wire brushing, or vinegar rinses.

Apply a compatible primer formulated specifically for galvanized metal, like etch or zinc-rich primers, to guarantee strong adhesion.

Avoid oil-based products that cause peeling. Use water-based acrylic or polyurethane topcoats for durability. Following these steps prevents paint failure and extends corrosion protection.

Here’s what you need to know to get lasting results.

Understanding the surface characteristics of galvanized steel is essential when preparing for spray painting, as these traits directly affect adhesion and finish quality.

You’ll find galvanized steel consists of a steel base coated with a protective zinc layer, including multiple iron-zinc alloy layers beneath the free zinc surface. This layered structure influences hardness and brittleness, which can cause flaking if bent. The coating is typically formed by dipping the steel into molten zinc, which bonds to the steel and becomes part of the surface chemistry, creating a durable zinc-iron alloy layer.

Visually, galvanized steel shows a spangled, speckled pattern with color ranging from shiny zinc to matte gray, depending on coating composition and weathering. The surface texture isn’t always smooth; it may be rough or treated to reduce spangles. However, welding or other heat processes can cause zinc vaporization that affects surface integrity.

The zinc coating provides corrosion protection through a physical barrier and cathodic action, but surface variability impacts how well paint adheres.

Before applying paint to galvanized steel, you must thoroughly prepare the surface to guarantee proper adhesion and durability.

Begin by removing dirt, oils, and residues using pressure washing, degreasing with emulsifiers, or steam cleaning depending on the condition.

For new galvanizing, neutralize with white vinegar before degreasing.

Next, create a microscopic profile through sweep blasting at low pressure or controlled shot blasting, ensuring zinc coating thickness remains intact.

Inspect the surface from 20 inches at an acute angle to confirm cleanliness, aiming for SSPC-SP 16 standards.

Keep humidity below 85% RH and surface temperature above dew point during preparation.

Address weathered or flaked areas with light profiling or feather grinding as needed.

Complete painting within the same shift to prevent oxidation and secure peak paint adhesion.

Proper surface preparation and coating removal are critical to reduce zinc fume generation and ensure weld quality.

Before you dive into painting, it’s super important to ensure that your galvanized steel surface is really clean. You can use abrasive pads or even blasting methods to get rid of any contaminants and create a surface that’s ready for paint. For example, sweep or whip blasting at 40 psi with fine copper slag or carborundum powder can create a microscopic etch profile that significantly improves paint adhesion.

Now, once that surface is clean, you might want to consider some chemical pre-treatment options like T-Wash or etch primers. These can really help by chemically modifying the surface, which boosts adhesion through specific reactions with the zinc coating.

Choosing the right mix of cleaning and chemical treatment is key. It makes a huge difference for how well the paint will hold up over time. So, take your time with these steps for the best results!

To achieve strong paint adhesion on galvanized steel, you’ll need to thoroughly clean and prepare the surface using specific techniques tailored to remove contaminants and optimize coating performance.

Begin with mechanical abrasion: lightly grind excess zinc or use a green scotchbrite pad with sodium carbonate to create a zinc carbonate film that promotes adhesion. It is important to remove bumps, runs, and drips by grinding or filing for newly and partially weathered surfaces to ensure a uniform coating.

Avoid sanding to prevent coating damage. Follow this by solvent cleaning with mineral spirits or isopropyl alcohol to eliminate oils and residues, drying the surface with compressed air to prevent flash rusting. Controlled mechanical abrasion helps to remove the brittle or porous layers formed by sulfur and phosphorus that degrade coating quality.

For weathered surfaces, wire brushing before a vinegar wipe-down removes oxidation.

Sweep blasting at controlled low pressure can also create a microscopic profile without damaging the zinc.

These steps guarantee a clean, flat, and chemically suitable surface for better corrosion resistance and paint application.

Although mechanical cleaning prepares the galvanized surface, chemical pre-treatment methods markedly enhance paint adhesion by modifying the zinc coating at a molecular level.

The T-Wash treatment, a modified zinc phosphate solution with copper salts, reacts with the galvanized surface, producing a dark grey or black discoloration that confirms effective treatment.

It is important to ensure that T-Wash must not be allowed to pool on horizontal surfaces to avoid surface defects and that any excess is removed with water. Despite a longer application time, it’s considered the best method, leaving the surface paintable for up to 30 days.

Using such treatments also helps in forming a corrosion-resistant coating that protects the metal beneath the paint. Etch primers chemically roughen older galvanized steel without visible color change, combining preparation with a protective coat.

Acrylic pretreatments use acidic components to etch and deposit a bonding layer, typically applied via spraying or dipping. Each method improves adhesion by creating a chemically receptive surface, essential for lasting paint performance on galvanized steel.

When selecting a primer for galvanized metal, you need to take into account the surface condition and environmental exposure to guarantee peak adhesion and protection.

For clean, new surfaces, water-based acrylic primers work well due to their chemical compatibility and fast drying. Proper surface preparation, including removal of oils and mill scale, is critical to ensure optimal adhesion.

For weathered or damaged areas, zinc-rich primers with 93% Type I inorganic zinc content provide galvanic protection and superior saltwater resistance, especially critical in harsh environments.

Avoid oil-based and alkyd primers since they cause poor adhesion and saponification on zinc surfaces.

Proper surface preparation, such as degreasing or T-Wash treatment, is essential before priming.

Apply primers evenly with brush, roller, or spray, following manufacturer instructions and allowing full drying time. Consistent film thickness and curing conditions help form a durable, cross-linked matrix that maximizes corrosion resistance.

Primer and top coat compatibility is recommended by using products from the same manufacturer to ensure optimal substrate protection paint system principles.

Choosing the right primer assures durable, corrosion-resistant coatings tailored to your galvanized metal’s specific needs.

Selecting the right paint type for galvanized steel guarantees peak adhesion, durability, and corrosion resistance. You should focus on paints designed to bond with zinc coatings and withstand environmental stressors. Proper surface preparation of the galvanized coating is critical prior to paint application to ensure long-lasting performance. In addition, thorough cleaning or removal of any existing coatings through mechanical or chemical methods can enhance paint adhesion.

Water-based acrylics deliver excellent adhesion and low VOCs, ideal for indoor use. Epoxy paints offer superior corrosion protection, especially in harsh chemical settings. Polyurethane coatings resist UV and abrasion, making them perfect for outdoor applications.

Latex-acrylics suit mild environments but require bonding primers for optimal outcomes.

Feel confident choosing paints that enhance galvanized steel’s lifespan. Trust epoxy’s resilience in tough, acidic conditions. Enjoy vibrant, long-lasting finishes with polyurethane topcoats. Protect your project with environmentally friendly acrylic options. Avoid peeling and corrosion by selecting compatible coatings.

Before you start spray painting galvanized steel, make sure the surface is meticulously cleaned and properly prepared to achieve peak adhesion and finish quality.

Begin by washing with warm soapy water, then rinse thoroughly. Remove oils or grease using a degreaser, followed by wiping with white vinegar to create a reactive coating. Since galvanized steel is coated with zinc to prevent corrosion, it is important to avoid abrasive methods that could damage the zinc protective layer. Proper surface preparation helps maintain the corrosion resistance of galvanized steel.

For abrasion, scrub with a sodium carbonate solution and Scotchbrite pad. Polish with ammonia and sand rough spots.

Apply a T-Wash solution carefully, avoiding pooling, and rinse excess. After surface preparation, apply a compatible primer immediately; etch primers or acrylic pretreatments work well.

Once the primer dries completely, spray alkyd-free or latex paint, starting within 12 hours to avoid zinc compound interference.

Maintain proper drying times between coats and complete painting promptly for best results.

When it comes to painting, surface preparation is key. You really need to make sure you’re removing any contaminants and creating a good texture for the paint to stick to. It’s not just a minor step; it’s essential for a successful finish.

Skipping surface cleaning can cause issues like blistering and delamination that lead to early paint failure, so thorough cleaning is critical to prevent these problems and maintain corrosion resistance. Proper surface preparation and corrosion-resistant primers are needed for metal substrates to ensure adhesion.

Now, don’t forget about primer! Using one that’s specifically made for galvanized steel can make a huge difference. It helps prevent peeling and boosts the durability of your paint job. Selecting primers compatible with galvanized steel enhances paint adhesion and overall coating longevity.

And let’s talk about paint types. Choosing compatible paints is super important to avoid any chemical reactions that could mess with the coating’s integrity. So, take your time to pick the right products for the best results! Using enamel paints with appropriate thinners also contributes to a smooth, durable finish on galvanized surfaces.

When working with galvanized steel, understanding surface preparation is essential to prevent common adhesion problems like paint chipping and peeling. Proper surface prep often involves using abrasive pads or blasting methods to create the necessary surface profile without damaging the zinc coating.

Zinc oxides, hydroxides, and other corrosion products form rapidly, creating a non-adhesive barrier.

Dirt, oils, and metal salts further compromise paint bonding. You must remove contaminants thoroughly and create a microscopic surface profile without damaging the zinc coating.

Timing is critical; apply paint immediately after cleaning and profiling to avoid new oxidation. Skipping proper prep risks peeling, flaking, or bubbling paint, underscoring why surface preparation matters.

Proper surface prep guarantees paint adheres firmly and lasts longer.

Frustration from paint peeling due to overlooked oxidation

Anxiety over hidden contaminants ruining your finish

Confidence gained by mastering precise cleaning techniques

Relief in knowing exact blasting pressures prevent zinc damage

Satisfaction from long-lasting, smooth paint adhesion

Although surface preparation lays the foundation, applying the proper primer is crucial to guarantee strong adhesion and prevent peeling on galvanized steel.

You must choose primers formulated specifically for galvanized surfaces. Options like AMP-UP 100 epoxy or MTN PRO wash primer convert zinc salts and corrosion products that otherwise inhibit paint bonding. Using a rust inhibiting primer such as Keen Zinc Aluminium Rust Inhibiting Aerosol provides additional corrosion protection and blends well with existing galvanized finishes.

Skip alkyd or oil-based primers as they cause adhesion failure. Apply primers immediately after cleaning to avoid zinc salt reformation. Proper primer application also helps maintain the passive oxide layer that protects galvanized steel from corrosion.

For fresh galvanizing, etch primers or direct-application coatings like Galvacoat work best. Use spray primers for uniform coverage and quick drying (15–30 minutes).

Employ pre-treatment methods such as the T-Wash zinc phosphate solution for weathered steel to enhance primer effectiveness.

Following these steps is essential to guarantee durable primer adhesion, preventing paint peeling and chipping on galvanized steel surfaces.

Selecting the right paint type plays a pivotal role in achieving durable adhesion on galvanized steel surfaces.

Alkyd-based paints react chemically with zinc, causing saponification that leads to peeling. Avoid these, including most common spray paints.

Instead, acrylic latex paints like Krylon H2O offer excellent adhesion with minimal prep and no adverse reaction.

Cold galvanizing sprays, rich in zinc, provide robust protection but limit color choices.

Oil-based primers repel zinc layers, causing failures, so steer clear of them.

Weathered galvanized steel with its natural zinc patina improves paint bonding, requiring less surface prep. The protective zinc carbonate layer that forms over time enhances corrosion resistance and paint durability.

Consistently achieving a durable painted finish on galvanized steel requires meticulous surface preparation, appropriate primer choice, and careful application techniques.

Achieving a lasting painted finish on galvanized steel demands careful preparation, the right primer, and precise application.

Start by thoroughly cleaning the surface with a water-based cleaner or degreaser, rinsing off residues, and verifying passivator removal with a copper sulfate test. Proper surface preparation is essential because adhesion loss is often caused by surface oxidation, which can prevent paint from sticking well.

Avoid hydrocarbon solvents to prevent adhesion failure.

Next, profile the surface using sweep blasting or light sanding with fine grit abrasives to guarantee proper paint adhesion.

Apply zinc-based or etching spray primers, steering clear of alkyd or oil-based primers that cause peeling.

Use compatible acrylic latex or epoxy-based paints designed for galvanized metal.

Spray thin, even coats from 10-12 inches, allowing each layer to dry completely in shaded, ventilated conditions. Applying several thin coats rather than one thick coat helps prevent bubbling, drips, peeling, and weak spots.

Finish with a clear coat to seal and protect the paint, ensuring long-lasting performance.

Wondering if you can spray paint galvanized steel outdoors in humid climates? Yes, you can, but you’ve got to prep properly first.

Remove white rust and zinc compounds with water-based cleaners and wire brushes.

Then apply an acrylic bonding primer designed for galvanized surfaces. Avoid oil-based primers as they cause adhesion failure.

Use airless sprayers at recommended settings and multiple thin coats to guarantee durability.

Humidity slows curing and promotes white rust formation, so it’s essential to take these precautions.

You should start painting newly galvanized steel as soon as possible after cleaning and prepping, ideally within 30 days if you use T-Wash pretreatment.

Fresh zinc coatings are smooth and non-porous, so immediate surface prep is essential for paint adhesion.

For weathered galvanized steel, you can paint without delay after degreasing and drying at least one hour.

Always follow primer drying times, typically three hours, before applying topcoat or spray paint.

Don’t throw the baby out with the bathwater. You can choose eco-friendly spray paint for galvanized steel.

Acrylic latex spray paints like Krylon H2O adhere well without harming zinc coatings and emit fewer VOCs.

Low-VOC primers, such as AFM MetalCoat, offer corrosion resistance with minimal environmental impact.

Zinc-rich coatings also provide protection with reduced toxins.

These options combine performance and sustainability, making your galvanized steel projects greener without sacrificing durability.

You can spray paint galvanized steel without removing old paint, but only if the existing paint is firmly adhered.

You’ll need to thoroughly scrape and sand away any loose or peeling areas first.

Then, apply a galvanized-specific primer to promote adhesion.

Follow with multiple light coats of your chosen spray paint, allowing complete drying between coats.

Skipping proper prep risks poor adhesion and durability issues on the galvanized surface.

Of course, who wouldn’t want to breathe in toxic fumes and splash paint in their eyes?

But seriously, wear a NIOSH-approved respirator mask with particulate filters to block paint vapors and zinc aerosols.

Don’t skip safety goggles; full coverage if you’re etching or priming.

Chemical-resistant gloves are a must to shield your skin from solvents and cleaners.

Finally, protect your clothes and environment with an apron and guarantee good ventilation throughout.

You might think spray painting galvanized steel is straightforward, but without proper preparation and the right materials, your finish could fail prematurely.

By thoroughly cleaning, choosing the correct primer, and using compatible paint, you’re setting the stage for durable adhesion.

Skip these critical steps, and you risk peeling or flaking. So, before you grab that spray can, make sure you understand exactly what your galvanized surface demands. It’s the difference between lasting success and costly redo.