Phone:

(701)814-6992

Physical address:

6296 Donnelly Plaza

Ratkeville, Bahamas.

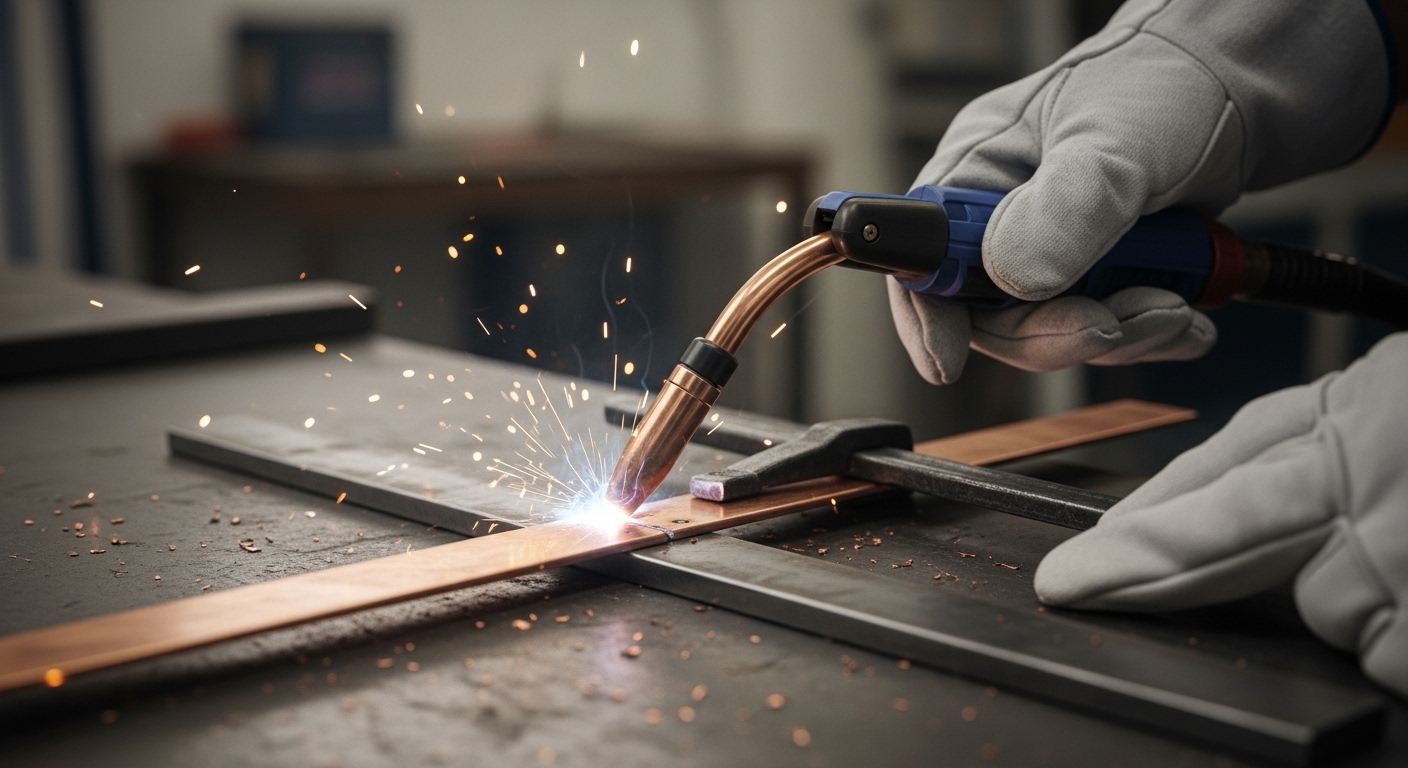

You can weld copper to steel, but it’s challenging due to copper’s high thermal conductivity and differing expansion rates that cause heat loss, distortion, and cracking risks.

You’ll need precise heat input control, thorough surface cleaning, and careful fixturing to guarantee strong joints.

Methods like TIG, MIG with inert gas shielding, or electron beam welding are best to manage thermal stresses and oxidation.

Understanding filler selection and process parameters is key if you want reliable, defect-free copper-steel welds.

Welding copper to steel presents several inherent challenges that demand careful control of heat input and joint preparation.

You’ll face copper’s high thermal conductivity, which rapidly dissipates heat, forcing you to increase energy to achieve proper fusion without overheating the steel.

The differing expansion rates between copper and steel can cause warping and distortion, so you must manage thermal stresses meticulously.

Additionally, the formation of brittle eutectic compounds at grain boundaries due to oxidation requires you to limit oxygen exposure and use precise shielding gas techniques.

Grass-roots dilution is another concern; it lowers thermal conductivity and promotes pores or cracking in the weld.

Preparing clean, oxide-free surfaces and securing tight joints are essential to minimize defects and guarantee a sound metallurgical bond when joining these dissimilar metals.

Preheating the copper and steel components can help reduce thermal gradients and minimize thermal expansion mismatch stresses during welding.

Managing copper’s exceptional thermal conductivity is critical to achieving consistent weld quality when joining it to steel.

Effective control of copper’s high thermal conductivity is key for reliable steel-copper welds.

Copper rapidly dissipates heat, forcing you to supply higher energy input to maintain adequate molten pool temperature.

This intense heat flow can cause uneven thermal gradients, resulting in warping or distortion at the joint.

Additionally, copper’s high thermal expansion rate demands precise control to prevent residual stresses and cracking.

You must also consider that rapid heat loss hinders fusion penetration, complicating bond formation with steel.

To mitigate these issues, preheating the workpiece and controlling heat input are essential.

Understanding copper’s thermal behavior enables you to optimize welding parameters, reduce defects like porosity and cracking, and ultimately guarantee strong, durable copper-steel joints despite their contrasting thermal properties.

Moreover, differences in coefficient of thermal expansion between copper and steel can create residual stresses that must be managed to avoid joint failure.

When you’re picking a welding method for copper-steel joints, it’s a good idea to think about using inert gas shielded processes like TIG and MIG. These methods are great because they help reduce oxidation and give you better control over heat input.

Plus, they can really make a difference in the quality of your welds.

If you’re looking for something with even more power, consider electron beam welding. This technique offers superior energy density, which means it can achieve deep penetration without the challenges posed by copper’s high thermal conductivity.

Understanding the unique benefits of these methods can really help you tackle common issues like cracking and distortion that often come up in copper-steel composites. So, take your time to weigh your options and choose the best method for your needs!

Additionally, using a non-consumable tungsten electrode with inert gas shielding in TIG welding can create clean, precise welds critical for joining dissimilar metals like copper and steel.

Selecting the appropriate inert gas shielded welding method markedly impacts the integrity of copper-steel joints due to the distinct thermal and metallurgical challenges involved.

You’ll find TIG and MIG welding effective for copper-steel composites, as they provide controlled heat input and inert gas shielding to minimize oxidation.

Use a silicon bronze filler with TIG to reduce iron dilution and prevent eutectic cracking at grain boundaries.

Preheating above 150°C helps counter copper’s high thermal conductivity and expansion.

Employ a 75% helium and 25% argon gas mix to enhance heat concentration and reduce porosity.

Precise surface preparation and clamping prevent warping and gaps during welding.

Controlling heat input and ensuring thorough surface cleaning are essential to minimize distortion and residual stress in copper-steel welds.

Although copper’s high thermal conductivity complicates conventional welding, electron beam welding offers distinct advantages for copper-steel joints by delivering concentrated, high-energy density heat that penetrates deeply without excessive thermal distortion.

You’ll find that this focused energy overcomes copper’s rapid heat dissipation, enabling a narrow, deep weld pool and improved fusion with steel. The electron beam’s vacuum environment eliminates oxidation and contamination, enhancing weld integrity.

Additionally, precise beam control minimizes thermal expansion mismatches and reduces residual stresses, which are common challenges in copper-steel joining. Unlike gas-shielded methods, electron beam welding maintains consistent penetration despite copper’s reflectivity and conductivity.

Consequently, when you need a high-quality, distortion-controlled joint between copper and steel, electron beam welding stands out as a technically superior choice, especially for critical applications requiring strong, defect-free welds.

Moreover, integrating precise current control during welding can further enhance weld quality by stabilizing the arc and minimizing defects in such dissimilar metal joints.

TIG and MIG welding stand out as effective techniques for joining copper to steel, particularly in composite plate applications where control over heat input is critical.

You’ll want to preheat plates thicker than 3mm to about 150°C to minimize thermal stresses and reduce cracking risk.

For TIG welding, using silicon bronze filler wire helps maintain iron content below 5%, preventing brittle eutectic formation at grain boundaries.

Applying a 75% helium and 25% argon gas mix concentrates heat and stabilizes the arc.

When welding thinner copper layers, deposit copper onto steel first, then employ a MIG backward tilt to guarantee adequate fusion without overheating.

Cleaning surfaces thoroughly and securing workpieces firmly reduces porosity and distortion.

These inert gas shielded methods effectively address copper’s high thermal conductivity and expansion challenges during welding.

Using argon as a shielding gas provides an inert atmosphere that protects the weld pool from contamination and ensures a stable, clean weld.

Electron beam welding really shines when it comes to joining copper to stainless steel. Why is that? Well, it’s all about the high energy density that this method offers. You see, copper has a tendency to conduct heat away quickly, which can pose some challenges during the welding process. But with electron beam welding, that high energy density helps overcome those thermal conductivity issues, making the process much smoother.

Moreover, this technique also minimizes the risk of cracking, which can often happen due to compound layer oxidation. That’s a big plus!

Plus, it effectively controls distortion, which is important since copper expands at a different rate compared to steel.

The use of high-velocity gas streams in welding can help remove molten metal quickly, improving joint quality and reducing defects.

When welding copper to steel, electron beam welding stands out for its ability to deliver high energy density precisely where it’s needed, overcoming copper’s high thermal conductivity and reflectivity.

You benefit from a concentrated heat source that penetrates deeply without excessive heat input, minimizing distortion and thermal stresses.

This precision enables a narrow, deep weld pool, reducing the risk of porosity and cracking commonly caused by copper’s rapid heat dissipation.

Additionally, the vacuum environment in electron beam welding eliminates oxidation, ensuring cleaner joints and superior metallurgical bonding.

You’ll find this method especially advantageous when working with stainless steel or thick copper-steel composites, as it maintains joint integrity and mechanical strength without requiring filler materials or extensive preheating, streamlining the welding process effectively.

Moreover, the ability to precisely control the heat input in electron beam welding allows for optimal temperature management, which is critical when joining dissimilar metals like copper and steel.

Electron beam welding addresses many difficulties inherent in joining copper to steel, but the process still contends with several metallurgical and physical challenges. You must manage copper’s high thermal conductivity, which rapidly dissipates heat, complicating stable weld pool formation.

The differing expansion rates between copper and steel cause residual stresses and potential warping. Additionally, you face risks of cracking from brittle intermetallic compounds forming at the interface. Surface oxidation can also introduce defects that weaken the joint.

Consider these critical challenges:

Addressing these guarantees sound copper-steel joints with electron beam welding. Controlling heat input and managing cooling rates are essential to prevent stress and cracking, similar to heat management techniques used in welding other dissimilar metals.

Optimize welding parameters carefully to leverage electron beam welding’s advantages for copper-steel joints. You need to set a high accelerating voltage, typically between 80-150 kV, to achieve deep penetration through copper’s high thermal conductivity without excessive heat input that causes distortion.

Maintain a beam current that balances fusion zone size and minimizes porosity, usually in the range of 10-30 mA. Control welding speed between 100-300 mm/min to ensure a narrow, defect-free weld pool.

Vacuum conditions must be stringent to prevent oxidation and contamination. Focus the beam precisely to exploit electron beam’s high energy density, enabling a minimal heat-affected zone and strong metallurgical bonding.

Precise control of heat input and cooling rates is essential to maintain joint integrity and minimize distortion in copper-steel welds, as demonstrated in pipe welding techniques.

Careful surface preparation is essential to guarantee a strong, defect-free weld between copper and steel.

You must remove oxides and impurities thoroughly, as they adversely affect fusion and promote cracking.

Preheating copper layers thicker than 3mm to at least 150°C minimizes thermal gradients and distortion.

Secure your workpieces with clamps to prevent gaps that cause weak spots.

Beveling edges optimizes weld penetration and reduces stress concentration.

Key preparation steps include:

Precise preparation directly impacts weld integrity and reduces defects in copper-steel joints.

After preparing the copper-steel surfaces to eliminate impurities and reduce thermal stress, your next step is to select filler materials that maintain joint strength and minimize defects.

For TIG welding, silicon bronze wire (1/16 inch) offers optimal compatibility, balancing thermal expansion and reducing cracking risk.

Make certain iron content in the initial weld layer stays below 5% to prevent brittle intermetallics.

In oxy-acetylene welding, adding copper filler to molten copper base helps maintain conductivity.

Use welding rods under 1.6mm diameter for composite layers to control dilution.

Avoid fillers with high iron content or incompatible alloys that promote eutectic formation at grain boundaries.

Selecting fillers with matched thermal and mechanical properties is critical to mitigate stress concentrations and guarantee metallurgical integrity across the copper-steel interface.

Since copper’s high thermal conductivity rapidly dissipates heat, you’ll need to apply sufficient energy to maintain weld pool stability and prevent incomplete fusion.

Controlling heat input carefully avoids thermal gradients that cause cracking and porosity in copper-steel joints. Additionally, managing oxidation and dilution levels is critical to maintain metallurgical integrity.

To prevent cracking and porosity effectively, focus on:

These measures help maintain a defect-free, mechanically sound copper-steel bond.

Although welding copper to steel presents challenges due to copper’s high thermal expansion, you can control warping and distortion by managing heat input and securing the workpieces firmly.

Start by clamping the components tightly to restrict movement during thermal cycles. Use preheating, typically above 150°C for copper layers thicker than 3mm, to reduce thermal gradients.

Apply welding methods that concentrate heat, such as TIG with a 75% helium and 25% argon shield gas mix, to minimize excessive heat spread. Control welding speed and power to avoid localized overheating, which exacerbates expansion differences.

Additionally, sequence weld passes strategically, allowing gradual cooling and reducing residual stress buildup. By combining mechanical restraint, controlled thermal input, and thoughtful welding sequence, you’ll effectively mitigate warping and distortion in copper-to-steel welds.

When welding copper to steel, it’s super important to prevent thermal cracks. You can do this by keeping a close eye on heat input and managing how quickly copper dissipates heat.

Also, don’t skip the surface prep! Make sure to clean everything thoroughly and consider preheating the materials. This helps avoid any oxide formation that could compromise the integrity of your weld.

And let’s talk about filler materials. Choosing the right one is key! Opt for something like silicon bronze with low iron content. This not only minimizes the chances of cracking but also boosts the strength of your joint.

When welding copper to steel, preventing thermal cracks demands careful control of heat input and joint preparation.

The high thermal conductivity of copper causes rapid heat dissipation, leading to uneven thermal gradients and stress concentrations that initiate cracking.

To mitigate this, you must regulate heat application and manage cooling rates precisely.

Preheat the copper-steel assembly to reduce thermal shock.

Use filler metals with low iron content to minimize brittle phases.

Apply controlled, moderate heat to avoid overheating copper.

Employ clamping to restrict distortion and maintain joint integrity.

Utilize inert gas shielding to prevent oxidation and embrittlement.

Since copper’s surface readily oxidizes and contaminants can severely weaken weld integrity, proper surface preparation is critical before joining copper to steel. You must thoroughly clean both metals to eliminate oxides, oils, and dirt.

Preheating surfaces above 150°C reduces thermal stress and improves weld quality. Make certain the workpieces are securely clamped to avoid gaps and distortion.

| Step | Purpose | Key Considerations |

|---|---|---|

| Cleaning | Remove oxides and impurities | Use mechanical and chemical cleaning |

| Preheating | Reduce thermal gradients | >150°C for >3mm thickness |

| Securing Workpieces | Prevent gaps and warping | Use clamps or fixtures |

| Beveling | Improve weld penetration | Prepare edges precisely |

Neglecting these steps risks porosity, cracking, and weak bonds in copper-steel welds.

Selecting the right filler material critically influences the strength and durability of copper-to-steel welds. You must choose fillers that minimize cracking risks and accommodate the differing thermal expansion rates.

Silicon bronze wire is a proven choice for TIG welding, guaranteeing low iron content and enhanced compatibility. Avoid fillers with high iron content, which promote brittle intermetallics.

Consider these factors when selecting fillers:

You can’t rely on copper-to-steel welds to withstand outdoor corrosion without extra protection.

The dissimilar metals create galvanic cells, accelerating corrosion at the joint.

Even with proper welding techniques, exposure to moisture and contaminants will degrade the interface over time.

You should apply protective coatings, sealants, or cathodic protection to guarantee durability.

Ignoring these treatments risks premature failure due to corrosion-induced weakening in outdoor environments.

Think of your copper-steel weld as a delicate dance between two partners with different rhythms.

To harmonize them, you should perform stress-relief annealing at 150-200°C, easing residual stresses and preventing cracking.

Follow with controlled slow cooling to avoid warping caused by copper’s expansion.

This post-weld heat treatment stabilizes microstructures and enhances joint durability, ensuring your weld won’t falter when exposed to mechanical or thermal stresses.

Yes, you must take unique safety precautions when welding copper to steel.

Copper’s high thermal conductivity demands controlling heat input to prevent warping or cracks.

Use proper ventilation to avoid inhaling copper oxide fumes, which are toxic.

Preheat thicker sections cautiously to reduce thermal shock.

Also, guarantee thorough surface cleaning to prevent oxidation-related defects.

Finally, wear protective gear suitable for high-reflectivity metals to shield from intense light and spatter.

Welding copper to steel generally reduces the electrical conductivity at the joint due to dilution and intermetallic formation.

You’ll see a drop because iron from steel mixes with copper, creating brittle compounds with lower conductivity.

Using silicon bronze filler or carefully controlling heat input helps minimize this effect.

Preheating and cleaning surfaces also improve joint quality, but you should expect some conductivity loss compared to pure copper connections.

Yes, you can successfully join copper-steel welds using robotic automation, especially with inert gas shielded methods like TIG or MIG.

Automation guarantees consistent heat input and precise filler addition, which is critical given copper’s high thermal conductivity and expansion.

You’ll need to program preheating, controlled cooling, and proper filler application to avoid cracking and warping.

Robotic systems also stabilize the arc and maintain peak shielding gas flow, improving weld quality and repeatability.

Welding copper to steel is like bridging two worlds with different rhythms.

Copper’s heat dances quickly while steel holds steady.

By carefully choosing your method, controlling heat input, and selecting the right filler, you’ll forge a joint that resists cracking and distortion.

Picture a seamless bond where metals meld without warping or porosity, achieved through precise technique and attention.

Master these details, and your copper-steel welds will stand strong under scrutiny.